FACILITIES

First-Rate Automated Production Line

- Over 30 production lines to fully meet all kinds of wet wipes production demands.

- Annual Production Capacity Up To 1 Billion.

Advanced Water Purification System

To guarantee the bio-pharma class EDI water in line with the standard of FDA USP grade.

To guarantee the bio-pharma class EDI Purify water system, Electrodeionization System (RO EDI Plant) is the best water treatment latest technology that removes the ions in the process RO water. Electro deionization System (RO EDI Plant) technique can achieve high purity of Deionized water with conductivity less than 0.1 μS/cm.

7 steps of water purification process to guarantee the bio-pharma class

EDI water in line with the standard of FDA USP grade.

-

Step 1

Multi-Media Filter

-

Step 2

Active Carbon Filter

-

Step 3

Ultrafilter

-

Step 4

First Reverse Osmosis Membrane

-

Step 5

Second Reverse Osmosis Membrane

-

Step 6

Electrideionization Device

-

Step 7

Ultraviolet Disinfection

Warehouse facility

We have quality storage facility for raw material and finished goods with a standard safety measures and convenient movement of the goods.

Warehouses play a key role in the manufacturing of quality products. They are responsible for receiving all goods, including packaging and labeling, and for releasing products. GMP rules are in place to ensure materials are stored and handled properly.

Bio-pharma Design Liquid Processing Infrastructure

316 L stainless steel construction of in-house blending systems equipped with world-class compounding techniques and completely automatic operation.

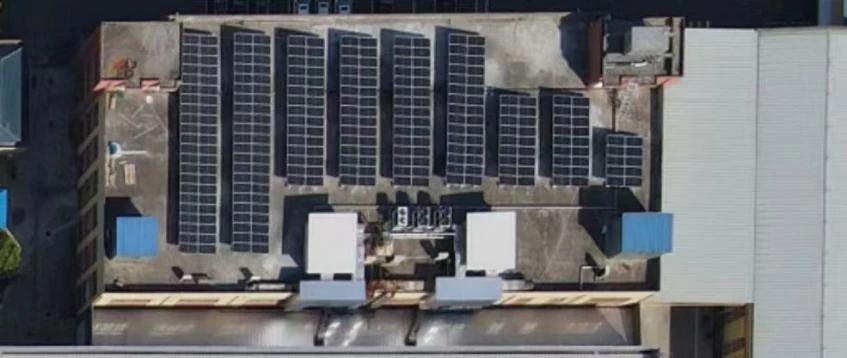

Eco-Friendly Practices

Solar-powered manufacturing process for energy sustainability, as the electricity we produced could power more than 1,000 families.

Joyalways has the confidence to provide the best service for you and your customers!